product description

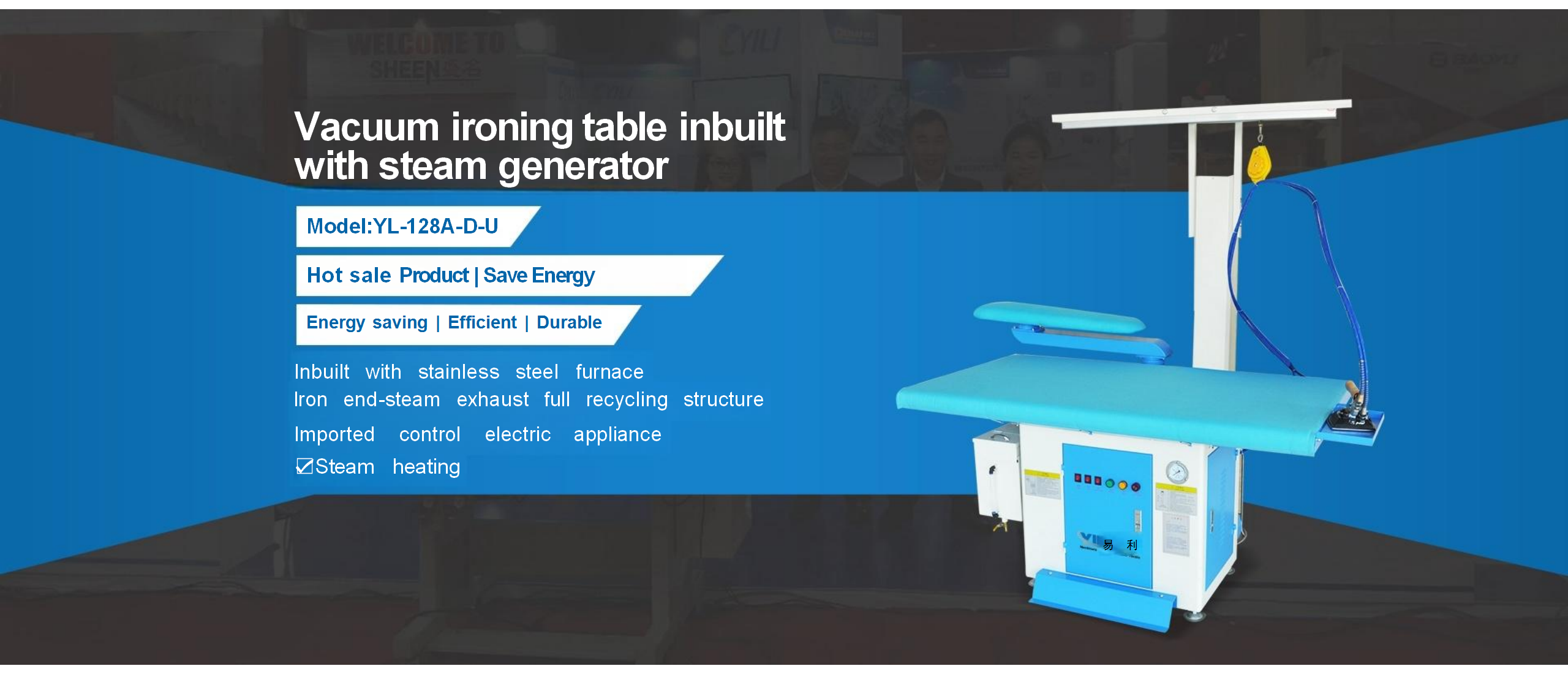

Vacuum ironing table inbuilt with steam generator

Energy saving YL-128A

Normal type YL-128B

| Technical Specification | ||

| Model | Energy saving YL-128A | Normal type YL-128B |

| Voltage&Frequency | 1PH AC220V/50Hz 0.8KW | 3PH AC380V/50Hz 0.75KW |

| Furnace Heating pipe power | 5kw | |

| Water Pump Power | 0.1Kw | 1.1Kw |

| Total power | 5.9KW/5.85KW | 6.9KW/6.85KW |

| Water tank capacity | 16L | |

| Steam pressure | 0.4 Mpa | |

| Steam output consumption | 7kg/h | |

| Table heating | Steam heating(Fixed temperature:80-100℃) | |

| Buck heater | Option | |

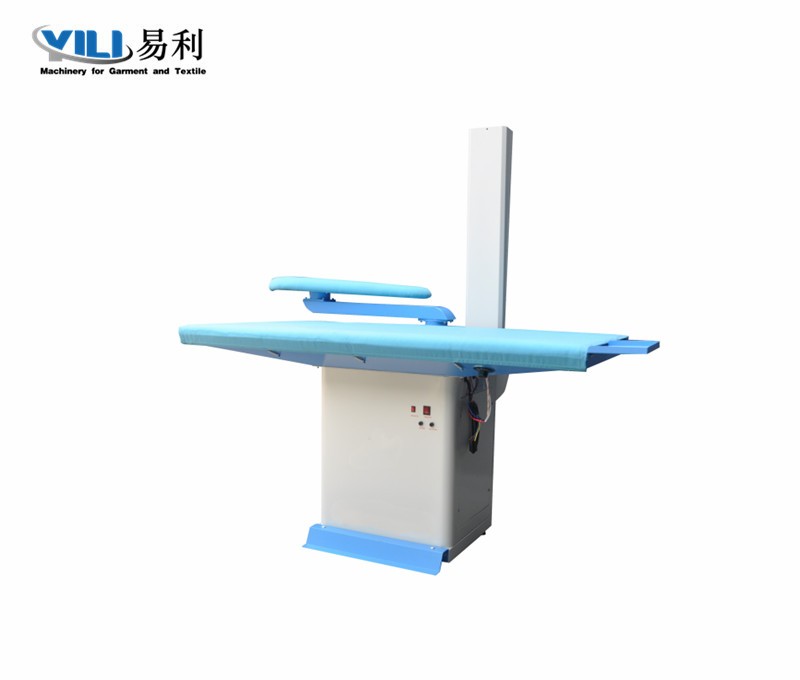

| Upward chimney | ||

| Iron hanger | ||

| Table size | 1500*780mm 1200*780mm/Customized is available | |

Feature

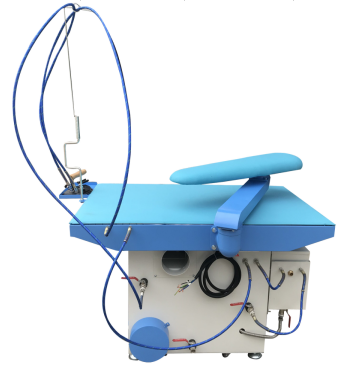

Integrated design, one table with one steam iron, automatically control adding water and heating, Suitable for different scale garment factories

Inbuilt with steam furnace, short steam pipe and low heating loss, to keep steam temperature and dry. It solves the shortcomings of using traditional large boilers, long steam supply pipelines,

high heating loss and wet steam

Energy-saving type advantages: The unique steam exhaust recycling structure ,makes fully use steam exhaust, which saves about 40% steam consumption compared with other same type products.

Solve the shortcomings of traditional steam exhaust directly returning to the water tank:

1.Makes the water pump heating and shorten its life 2. The water vapor generated by the boiling water in the water tank will not only affect the working environment, but also make the clothes easily

to getting moist and mold

Stainless steel furnace, steam without stains, to avoid making the clothes dirty

Without changing the heating pipe power, the external volume of the heating pipe is increased, the heat receiving area of the water inside the furnace is increased, so that the heating and heating temperature will be speed up, the steam volume is sufficient

Equipped with moving casters for conveniently moving

| Type | Feature | Average hourly electricity consumption | National patent product Energy saving, environmental protection, high efficiency |

| Energy saving type | Steam Exhaust recycling using | ~3.8kw | |

| Normal type | ~6.2kw |